|

FAQs about DIY Tanks, Sumps Made of

Acrylic

Related Articles: Making Your Own Tanks, Sumps, Designer Marine tanks, stands and

covers, Aquarium

Repair, Marine System

Components, Canopies, Covers & Lighting

Fixtures,

Related FAQs: DIY

Tanks, Sumps 1, DIY Tanks/Sumps

2, DIY Tanks/Sumps 3,

DIY Tanks/Sumps 4, & FAQs on

DIY Tank & Sump : Design, Shape/Size, Materials, Tools/Construction/Sealants, Plumbing... DIY

Glass Tanks, DIY Wood Tanks,

DIY Other Material Tanks... &

Tanks, Stands, Covers, Custom Aquariums, Stands,

Covers..., FAQs on Commercial, Custom and DIY Tank:

Design, Shape, Materials: Acrylic,

Glass, Other... Tools, Location, By Make/Brand/Manufacturer Name, & Acrylic Tank Repair,

|

Acrylic Tank Fabrication

Not really a

question. Today's list of questions included some about making

you own tank. TAP Plastics, a somewhat local firm that deals

primarily in acrylic, has a website that includes a downloadable

set of documents concerning how to work with acrylic sheet

goods.

The link to their info page:

http://www.tapplastics.com/plastics/plasticsinfo/acrylic.html

Regards,

Charlie H.

<Thank you for this link. Will post. Bob Fenner> |

|

Acrylic Aquarium build. 1/20/19

Hi guys/Bob,

<Good morn Mike>

I’ve built a custom (cell cast) aquarium 60”X36”x 24.5” high top and are 1/2”

acrylic, side panels are just shy of 3/4” acrylic. Joint gaps before glue are

.02”. Glue used is Scigrip 42.(you can’t beat 4000psi) Some small bubble here

and there and some crazing. Tank holds water fine. Long side panels bow measured

from Center with a two foot level,

<A note here: I'd use a longer level... >

I get a 1/16” gap from left to right at either end of level. From top to bottom

I get 1/8” gap at either end of my 24” level. Is this bowing ok?

<Mmm; likely so; considering the thickness of acrylic used here. Are you sure

the stand itself is level?>

I get very little bow at the short ends of my tank. I drained half the water and

found the bow very similar than when the tank is full.

<Ah, yes; the material is not going to bow itself>

I was planning on running an old Tunze wave box on the tank as part of a stress

test to test the seams. Tank panels were laser cut and all lasered edges were

shaved off till stress bowing of the panels were relieved.

<Oh! Neat! Not a worry then.>

One of the well known tank manufacturer wanted to make this tank out of 100%

1/2” acrylic. I totally didn’t want that!!!

<Agree/d>

Thanks for your help.

Mike

<Thank you for sharing. Bob Fenner>

|

.jpeg) .jpeg) |

|

Re: Acrylic Aquarium build.

1/21/19

Hi Bob,

<Mike>

The tank isn’t perfectly level but I did make sure there was no twist in the

stand before adding water to the tank. I used a high quality level. Accurate

to .0005”!

<Wow>

I can certainly use a longer level or straight edge for the 60” but I was

using it as a brief reference. I would imagine 18” past my 2ft level at

centre would be 1/8-3/16” gap at either end. I can confirm this when I do

another water test.

<Yes I would>

I have to ask you again. How comfortable are you with the thickness of

acrylic I used, high quality glue, my application method and amount of

bowing?

<Am very fine w/ all>

Best regards Bob!

Mike

<Cheers, BobF>

Re: Acrylic Aquarium build.

1/30/19

Hi Bob,

<Hey Mike>

How much bulging is too much on the long side at mid height going horizontally

(gap at either end of the 60” length on a straight edge?

<Mmm, maybe a half inch... going back to your other dimensions; particularly the

24.5" height. Some acrylic is softer than others... the flexing is not such a

big deal (right, define "such"); but bulging rarely indicates a propensity for

structural failure>

I’d like to know what the maximum Gap your comfortable with regarding 3/4” thick

acrylic. We’ve established 1/8” vertically at Centre.

<That's more than fine mate. I would not worry Re.>

Thanks,

Mike

<Welcome. Bob Fenner>

Re: Acrylic Aquarium build. 1/31/19

Thanks Bob!!

<Welcome Mike>

Yea tank is 24.5” high but the 3/4” panels are 23.5” tall alone. That worked in

the acrylic calculator on the DYI guys website. I could always cut the tank and

make it shorter in height and re-glue the top back on.

<I'd leave all as is>

Thanks so much for your input Bob. It’s a heavy tank going on concrete slab.

<Thank goodness; and hey, could be worse. Think if it were made of glass! >

Best,

Mike

<And you, BobF>

Re: Acrylic Aquarium build. Holes, placement

2/1/19

Bob,

<Mike>

I forgot to ask. I have to drill 2-2” holes for bulk heads half way up on the

36” side of the tank and off to the side. Also a 1” or 1.25” bulk head closer to

the top of the tank on that same side. The return from pump is a Varios 8 from

reef octopus. We’re talking up to 2700Gph . Should I be too concerned about the

hole locations? Ex. Proximity to each other? Proximity to side corner or top?

Any risks?

<Not too much of a concern. Please read over our replies to such:

http://www.wetwebmedia.com/pbholessizeplace.htm

and the linked files above>

( regarding overflow bulk heads being half way up the side. It gives me the

option to run the tank at a lesser volume in case there’s a weight bearing load

issue.

<... as in on the floor? I'd have a structural engineer into check unless this

is a concrete slab>

Also, a leaky bulk head will only drain half the tank. ;)

<Yes... but, a problem in the plumbing will drain it down this far. DO search

WWM re Overflow Designs... I'd mount mine near the top... Bob Fenner>

Mike

Re: Acrylic Aquarium build. 2/15/19

Bob,

<Mike>

I might as well run this by you. I noticed along one side at the bottom, the

bottom isn’t straight.

<?>

It seems that the bottom isn’t perfectly flat and straight. 1/16” over 40” of

the 60” length. I may cut the glue out. Create a proper gap and re fill with

glue.

<Glue? What sort of product? Acrylic tanks are generally solvented, not glued.>

In case you don’t understand, the bottom fell away 1/16” over 40” of the 60”

length.

<Am daft I guess... "fell away"?>

Or should I just leave it?

Mike

<I would likely leave it; modify the stand, or insert a foam sheet under to take

up some of the stress here.

Bob Fenner>

Re: Acrylic Aquarium build. 2/15/19

Bob,

<Mike>

Epoxy weld on 42. Side panels are standing on the bottom, in design.

<Yes; a solvent, not much "body" at all... And yes to the sides as they are:

standard practice>

When gluing the bottom. I had .02” clearance all the way around the bottom

(manufacture recommended min. Gap) except one area that was not in line.

<... gaps made with... piano or other wire are de rigueur. Not in line I don't

like>

The gap opened to 1/16” to produce that bulge but that bulge was in turn filled

with the epoxy unknowingly. (Epoxy SG42.) I will likely saw the seam and clamp

straight and re fill with SG42 unless you object.

<Mmm; I hope I don't come across as (too) lazy; but I'd test, use this tank as

is>

The rest of the bottom is perfect. The tank will sit on two layers of 3/4”

plywood.

<And a thin sheet of Styrofoam twixt the tank and wood please>

Regards,

Mike

<Cheers, B>

Re: Acrylic Aquarium build.

2/20/19

Hi Bob!

<Miguel>

How about 1/2” interlocking children’s black foam play mat cut to the footprint

of the tank instead of 1/2” pink Styrofoam for it to sit on.

<Well; thicker than it need be; but mighty fine! B>

Regards,

Mike

|

|

Acrylic Coast to Coast Overflow 12/19/17

Good Day,

I'm building an acrylic tank 60" x 60" x 30" out of 1" cast with top

bracing. Instead of 1 long opening on the back, I have 2 cutouts, 2-1/2" x 18"

for a semi coast to coast overflow.

<Mmm; am concerned re the structural integrity of the back now....>

They have a 6" gap between them. The top will attach in 3 places for added

strength.

<Good for the top; what about the back?>

I made the overflow box 40" x 12" x 12" . 1" thick material. Inside dimensions

are 38" x 11" x 11". I plan on having it 1/2 to 3/4 full of water when running.

My question is about the support needed for the box.

Will welding it to the tank be enough support or should I weld triangular

support gussets under it. If so will 2 work (one on each end) or will it be

better to put 3 under it?

Cheers,

Dana

<Good questions (whew!). I would add the gussets you mention. As large and as

many as you deem reasonable. Bob Fenner>

Re: Acrylic Coast to Coast Overflow 12/19/17

Bob

Here is the tank on its side. I took a picture of the back so you can see the

cutouts.

You think the back will be a problem even with the top having those 3 places as

attachment points?

<Too much stress on the remaining span... I would not have cut this tank like

this...>

Cheers

Dana

<I do hope there aren't (catastrophic) problems here. Bob Fenner>

|

cutouts on right vertical

cutouts on right vertical |

|

Acrylic Aquarium Question- help

10/25/27

Hello-

<Howsit?>

I’ve been reading your forum on Acrylic seams, cracks, etc and wanted to ask Bob

Fenner a question. I can’t see where to post a question and was wondering how to

reach him? I just built my first aquarium, it’s 300 gallons and I have some

concerns about the seams that I wanted to ask him. Can you advise where to ask?

<This is it mate. Please ask away. Bob Fenner>

Thank you!

David

Re: Acrylic Aquarium Question- help 10/25/27

Hey Bob! So, like I said I just finished my first build, of a 300G acrylic for

my home. It’s 1” acrylic on all sides and 1/2” on the top and bottom.

<? I encourage folks to have tops, bottoms of acrylic tanks at least the

thickness of the rest... thicker if the tank is tall>

It will be set on top of a solid wood stand with a 2” thick concrete countertop.

Dimensions are 72x24x30. Everything was cut with CNC machine and all the pieces

are square/plumb, etc.

<Good>

All my sides came together perfectly and my top went on perfectly... my only

concerns are with the bottom piece. I did the bottom last, and with all the

weight (even using the pins method) the weld-on #4 didn’t create solid clear

joints like everywhere else. There were like 5-6 spots total around the whole

base where it created pockets that sealed and I just couldn’t wick it in there.

Doing this over, I think I would’ve used the 2-part epoxy, but overall the

solvent did really well considering it’s 1” thick acrylic. So, all things

considered I’m happy that the joint pockets happened on the bottom piece rather

than the corners or the top (I think?) take a look at the attached pics and let

me know your thoughts. Would a catastrophic failure be possible if only the

bottom seams are like this, since it’s fully supported underneath? Like I said,

90% of the bottom piece is good, but there are several pockets that are there.

Thank you for your help!

David

Ps. After reading all the forums, I realize I could have added doweling if need

be, but I already added a thick bead of #16 around all the bottom seams for

extra support. I filled the tank twice and let it sit for a couple days and had

no leaks, no movement, no cracks or hazing, etc.

<Mmm; okay... IF there is further concern (or reason for concern!), I would add

the doweling all around the inside bottom. Bob Fenner>

|

|

|

Acrylic Viewing Pane 3/25/17

Hi all,

<John>

I am hoping to have built a 2.8 metre by 2.8 metre by 1.5 metre high cement

panel aquarium. The viewing window will be about 2.8 metres long by 1.5

metres high. Viewing window supported around all 4 sides by cement paneling

with rebate. Can you help with an estimate of the thickness of acrylic

window.

yours

John

<Yes; depending on the quality of the acrylic sheet available and your

adverseness to risk and bowing, 60-70 mm... Here's a handy calculator:

http://diyfishkeepers.com/AcrylicThicknessCalculator.htm

John Wilkins

Rural GP

Cygnet Tasmania

<Bob Fenner, San Diego, CA>

|

Top view

Front viewacrylic thickness

further query 6/6/17

Hi Guys …. thanks for your reply .. you linked me with your acrylic

calculator. I have indeed previously used this calculator on my specs.

<Okay>

window 1.5m height, 2.75 m length... your calculator suggests thickness

6.6cm

However I still have some queries about this result

I understand that the calculator assumes an all acrylic aquarium

My build is 2.8 metre by 2.8 metre by 1.5 metre high cement aquarium.

My intended viewing window is supported around all 4 sides by cement

paneling with rebate for the acrylic pane.

My question is … does this 4-sided cement support change the required

acrylic pane thickness.

<IMO/E no; I would go with as thick as you can afford; a minimum of 6.6 cm.>

I have worn myself out reading so many discussions on this subject … my

brain is getting a bit frayed around the edges.

<A few pertinent notes: There is a definite "spectrum" of acrylic quality...

some are softer, given to more/less bowing, scratching, clarity, uniformity

in thickness....>

I am hoping your experts can give me your definitive estimation of the

thickness I need for this project

yours

John

<If this were me, my project... thicker. Bob Fenner>

Re: acrylic thickness further query

6/8/17

thanks for your reply. I will make sure the viewing pane is of the best

quality acrylic. Bob Fenner... so if if was your project ... exactly what

would you ask for ... thickness and quality

<Best quality available and at least 2.5" thick; a note: 2" if good glass

available rather than acrylic>

Cost is not an issue at all .. I am budgeting $150,000 for the whole

project. My engineer would really like an idea of the viewing-window specs

as it is not his area of expertise. I have attached a diagram for your

interest

John

<You sent this w/ your orig. query. Cheers, Bob Fenner>

John Wilkins

Cygnet Tasmania

|

Acrylic tanks

11/18/14

I want to attach two acrylic tanks together to make one large tank. Is

this possible? How should I go about doing this? Danielle

<Mmm; either by cutting off a side from each tank, or drilling a hole in

each and connecting them with a cylinder of acrylic... See WWM re the

use of solvents with acrylic. Bob Fenner>

Q & A about acrylic 11/19/13

Thought this was interesting Bob, might want to share it.

http://distributionbizwiz.wordpress.com/2007/08/23/acrylic-q-a/

[email protected]

<Ah yes; will do. B>

Mixing and matching acrylic thickness

11/6/12

Hello, I know you guys have answered a zillion questions about acrylic

tank construction and hope you have time for one more. I'm building one

using 1.5" Polycast GP dimensions 120x36x36 and was wondering if I would

be able to get away (safely) with using 1.25" thickness for the bottom.

<I would make this bottom the same 1.5" thickness>

Although I've seen tanks this size use thinner material I really want to

minimize bowing and have some 1.25 in the garage that is a few years old

Id like to make good use of.

<I'd use it/this for the top instead>

I will probably use #4 vs. #40 because I'm not able to anneal this tank

and will be assembling it on site. Do you think Weld-on #4 is ok for

something this size?

<Should be>

Thanks for all of the help you've

provide in the past.

<Welcome. Bob Fenner>

Please Help/DIY/Acrylic Refugium 1/25/12

Hello

<Hello Scott>

I got your site from a friend of mine. I am building a 35gal refugium

for my 75gal reef tank out of 1/4" lexan (polycarbonate). The only

thing I need to know what glue or cement to use to assemble it ? I have

asked so many people but nobody can say for sure about it and don't

want any toxins in the water. This is probably a stupid question to you

guys but if you can help that would be great !

<The Weld On brand of acrylic cement is what you need.

It's available in different viscosities depending on how fast you

want it to set up. Marc Levenson has a tremendous amount of

information on his site as to working with acrylic.

http://www.melevsreef.com/allmysumps.html>

Thank you for your time

<You're welcome. James (Salty Dog)>

Scott Early

DIY Aquarium, Lg. Acrylic 1/31/11

Hello Crew,

<Hello Tina.>

Once again I am back to ask more questions. I am in the process of

designing an aquarium for my husband to build me (He is a carpenter,

but never built an aquarium). Its going to be about 350 gallons; the

dimensions are 96 long x 36 wide x 24 tall. The design is a bit odd and

I have never seen one constructed this way, but I have a couple reasons

for it.

<Hmm, I have built a few of similar size and it is very nice! But

this is way too big a project for a first aquarium, I do hope he has

acrylic experience. I would check around with local clubs or forums to

see if there is somebody that has done this before that can assist

here.>

To start, the actual aquarium will be constructed from acrylic. I would

like your advice on the thickness of the acrylic. I have done a lot of

research and found so many different answers for this question. I

was

thinking 3/4" inch thick, but I have read people using ½

inch.

<Definitely the thicker of the two for this dimension. Some would do

this in 1/2", but the tank would bow, be quite unsettling.>

I also wanted to know what weld on product number you recommend? I was

going to order weld on

# 4, but I wanted to make sure before I order it.

<Would be my choice, with some #16 to fill any gaps you may end up

with.>

Do the corners of the acrylic have to be bent?

<No, with these dimensions you would be hard pressed to find a sheet

large enough anyhow.>

Or, could they just be bonded together with the weld on flat surface to

flat surface?

<Yep.>

Can I spray paint the back and two sides of the outside of the acrylic?

If so, what paint do you recommend?

<I know many have used Krylon Fusion for this, but I personally

would simply use a water based roll on paint such as basic

latex.>

The top acrylic will be 4 around the top, and 3.... 4 braces going

front to back. Should this

all be one piece? Or, can it be done with scrap pieces?

<It can be done with scraps, but one whole piece with a large radius

in each corner is better. With the scrapes you end up with 90 degree

corners where the supports meet. That is a high stress point and can

lead to failure.>

Now the odd part is I have designed a 3/4 plywood frame for the bottom,

1/2 plywood for the complete back and both sides. The front will be

framed 4 all around. The plywood will have 2x4 beams vertically every

12 and horizontally will have a 2x4 top and bottom beam. They will be

glued, nailed and have metal brackets. Installed on the outside of the

beams will be a decorative painted wood.

<Are you talking of framing around the aquarium or under it? If

around I would really take a look on the net for plywood tanks with

just an acrylic or glass viewing panel.>

Should the beams be closer?

<Every 12" is more than enough.>

Is the thickness of the plywood going to support the acrylic any

better? Or will there be a problem? Would you recommend thicker

plywood?

<The thicknesses you list will be fine.>

Should I put something between the acrylic and the plywood?

I was thinking of using foam insulation, would that be ok to use?

<Is exactly what to use, the rigid Styrofoam type.>

What would be the safest paint to use on the exterior wood? I wanted to

use interior latex paint, but I want to make sure it will be safe.

<Just fine.>

This aquarium will be on the first floor in my home. My husband is

going to reinforce the floor by framing support beams in the basement

under the tank. The tank stand will also be built by my husband.

<Ah, so I do take the above regards framing around the tank. With

the dimensions you list and the thicker acrylic there will be no need.

If you are going to frame it in I would simply go with thicker plywood

all around and search the net re plywood tanks.>

I am not sure where to start with the stand, my husband was thinking of

framing it with 2x4 every 6, would that be suitable?

<It will more than enough. No need for every 6".>

If so, should he do that throughout the whole inside of the stand?

<No, but would be beneficial to have some cross beams at the top to

support the plywood in the middle.>

Or, what would you recommend?

<Take a look at the tank and stand calculators on GARF.org. I

don't agree with it all, for instance it will recommend 1/2"

for your tank because it is 24" tall (there are other factors),

but it will give you the basic idea on assembly and stand

construction.>

I hope you can understand my aquarium design. I am hoping the plywood

will make it sturdier.

<I do and would like to reemphasize, this is a huge system to build

as a first project. At the very least get some acrylic scrap to

practice with!>

Thank you

Tina

<Welcome, Scott V.>

Re: DIY Aquarium, lg. acrylic, plywood now

1/31/11

Hello Scott V,

<Hello again!>

Thank you for your quick response.

<Happy to help.>

You have made it very clear that this is too big of a project for the

first timer.

<I speak from a very assorted mechanical background and bad

experiences!>

I assume you mean the acrylic tank, and the plywood tank of this size

would be safer for a first

timer.

<I don't like these tanks, is just my personal taste, but they

have become very popular due to cost and ease of fabrication IMO.

Especially with your husband's background, I really think this is

more appropriate.>

I originally wanted to do the plywood tank, but I was worrying that it

may not work. My biggest concern is my fish being safe.

<They work great. In some ways (especially if fiberglass

reinforcement is used) they can be much more durable.>

My husband was going to practice some with the acrylic, but if you

think our best bet would be the plywood tank. Then thats what I will

have him do, I am going to do more research on plywood aquariums, but I

still would like your opinion on a few things.

<Sure. I can tell you as somebody that has done acrylic work for

many years now, I am still hesitant to take on big projects like this.

There is just too much stuff you do not learn until it is too late.

People look at the cost of Acrylic and the "ease" of

fabricating. This leads to many "I built it myself" type

stories in the forums. Well, let us wait and see.>

If we do the same dimensions 96L x 36W x 24T, what type of plywood?

Will 3/4 plywood with the framing I explained in the last email work

fine?

<Yes.>

I read DIY aquariums on GARF.org, it shows to put glass in the plywood

tank to use aquarium silicone; will that work if I use a sheet of

acrylic?

<It will. Really silicone does not form a mechanical bond of any

significance with plywood, marine resin or acrylic. It is merely a

sealant. Water pressure holds it in place. For my money I would go

glass for a viewing panel here. Cheaper, more scratch resistant and the

problem with glass (edges and precise dimensions relying on others)

does not really come into play here. That is unless you suspect you

will have Babe Ruth in there swinging something.>

If not, what should I use to bond the acrylic to the plywood and have

no leaks. That site also said for my size to use 1/2 glass, does that

also go for the acrylic or do you still suggest the 3/4? GARF.org gave

some great information on the proper epoxy to use that will be safe for

my fish.

<Oh yes, the calculator is great for this stuff. With both acrylic

and glass (there is a plywood with acrylic choice) they recommend

1/2". I would go with that for glass, but still 3/4" for my

taste in acrylic. Fact is minimum acrylic thicknesses, while they do

work fine, will bow out in the middle and look unsightly. It kills me

to constantly read from manufacturers of acrylic tanks that acrylic has

less distortion than glass, then they build it out of a thickness that

makes it look like you are viewing your tank from a globe type

fishbowl. But again, that is just my opinion, I hate bowed and wave

front tanks for the same reason. I refuse to own or install those.

People ask me to and I say no. Few are happy with them, even far fewer

buy the same again.>

Are plywood aquariums dependable?

<Yes, very much so when constructed properly. With a carpentry

background your husband should be more than capable. The waterproof in

mostly just a bit of busy work!>

How long do they usually last? Should the epoxy be reapplied every so

many years? Or, is it durable for

a long time? In your opinion, how safe are plywood aquariums?

<To all of the above, I really have no issue, nor have seen any, so

long as the look is what you want. I just personally like the whole

front at the least opened up for viewing. If a "viewing

window" is a look you like I would not hesitate a bit to do

this.>

Thank you so much for your time,

Tina

<Welcome!>

Re DIY Aquarium, Lg. Acrylic 1/31/11

Hi Scott,

I might add that Marc Levenson has a tremendous amount of information

on his site as to working with acrylic.

http://www.melevsreef.com/allmysumps.html

James

Did I Mess This Up, Lg. acrylic tank bowing

9/8/10

Hello WWM

<Hello Josh>

Question on acrylic aquariums. I purchased a 500 (more like 480) gallon

acrylic aquarium. I checked the bonds all around it and all are solid

with no gaps/hazing/bubbles etc. I was actually impressed with the

seams. The tank dims are 8 x 3 x 32 inches. Here's where I got a

little uneasy. I test filled the tank and it bowed about 1/2 to 1 inch

(eyeballing here). Upon

inspection I noticed the material was 1/2 or 5/8 inch!!!!! All I've

seen with most tanks this size is 3/4, but they were 36 tall? Am I in

trouble here? Again no major stress signs just normal wear, and the

seams are solid. Did I just buy a 500 gallon sump?

<All large tanks will have some bow in them when filled and is not

cause for alarm. I'm guessing this tank was previously owned and if

the original owner had no problems, you should not as well. But to be

on the safe side, how about sending us a pic of the tank (filled) taken

from the top.>

Thanks

<You're welcome. James (Salty Dog)>

Josh

FW Ray... hlth. 12/30/09

Hey guys I was checking around your site for some information before

wasting your time with questions so I'll keep it short. I have a P.

reticulata ray and it seems to have lost a lot of its tail during

transportation (the stingers are basically a cm from the tip of the

tail).

It's not injured any more, but I was wondering if the tail would

ever regenerate?

<Often times can/does... "if" the area is not

"too" decomposed back>

The specimen is still small around 5 inch disc diameter. The other

question was I need to design a final custom tank for her and had a few

questions. I've heard acrylic was lighter than glass but hard to

work with,

<Not hard, just different to cut, anneal (rather then glue)... have

done extensive work w/ both>

plus I like the no shattered glass aspect. Are acrylics hard to

seal?

<No>

Would you recommend acrylic or glass for a large shallow ray tank

6'x3'x18"?

<Acrylic over glass myself>

Finally would a tank this size be able to be supported by a standard

floor (1st or second story) due to the surface area spreading the

weight or would I be better off on the concrete basement floor?

<Yes... think of the weight per square foot, inch of a lady in high

heels... may need to have the stand/base shimmed to level. See WWM re

both material use in tank construction and stands...>

.....Thanks in advance for your time.

Sorry I just remembered one more thing...Does Potamotrygon

reticulata

possess 2 stingers or is the second one a replacement for the 1st as it

is shedding off?

<... One... are you referring to claspers? Bob Fenner>

Re: ray...sorry last email was an accident... Acrylic tank

const. 12/31/09

Thanks alot

<There's no such word>

for your help..sorry for confusion I accidentally sent the last

email

before typing anything. You better be getting paid for answering

questions

<Nope. Something of much greater and lasting compensation; the

knowledge of having help others of earnest need, desire>

because you obviously know what you are talking about. When you say

annealing acrylic tanks I have a few questions. Would this be

accomplished with a heat gun?

<No; solvent. Read here: http://wetwebmedia.com/diyacrylic.htm

and the linked files above>

The FAQs I've read about acrylics involve sealant

<Not sealant... as in, there's nothing "left" between

joints>

rather than heat. I'm assuming attaching them by essentially

melting them together would create a much better seal (assuming I

don't end up creating gross melted uneven corners).

<There is such a process as "sonic welding" of large

acrylic panels... as in for large, mainly public aquariums; but in your

case solventing is what will be done>

I forgot to ask would a 6'x3'x18" acrylic need center

bracing <... depending on the thickness of acrylic used>

or is there enough surface area already?

<Enough for what?>

And finally to clarify "> Sorry I just remembered one more

thing...Does Potamotrygon reticulata

> possess 2 stingers or is the second one a replacement for the 1st

as it is shedding off?

> <... One... are you referring to claspers? Bob

Fenner>"

I meant the stingray is apparently female but has two stingers on

it's tail. Is this a species I.D. characteristic or can many

species possess more than one stinger during part of the shedding

process (i.e. will she lose the second stinger). The further back

stinger appears to be partially unsheathed from stinging or maybe the

stinger shedding process that I'm not 100% familiar with. Once

again thanks so much -Nigel

<Yes to the shedding of multiple stingers. Usually there is one

functional, with one more growing to replace it. BobF>

Building my own acrylic aquarium 9/23/09

To whom it may concern,

I have been reading over your FAQ's on DIY acrylic aquariums all

night.

I just have a few questions if you don't mind?

I plan on building an acrylic aquarium that measures 96Lx48Wx24H.

According to the garf.org website it recommends that I use 1/2"

cell cast acrylic.

<Or thicker... the 1/2" is going to bow a bit in the middle of

the long panels>

After reading over your FAQ's I came across a response were it

stated that if the aquarium is wider that 32" the thickness of the

acrylic must be at least 3/4" thick.

<Yes>

Upgrading to this thickness is out of my price range. Would 1/2"

acrylic suffice?

<If the bottom is sufficiently supported (as in 4 by 4's) yes...

just the bowing in the mid front and back panels...>

When building the acrylic aquarium do place the walls of the aquarium

on top of the bottom acrylic sheet or do you place the walls on the

side of the bottom sheet?

<On top>

I do apologize if you have answered this question already. I must have

overlooked it when I scrolling through FAQ's.

Thanks for all that you do!

Brent

<Glad to help. I would get some help here from folks who have

acrylic experience. Not hard work to do, but easy to make simple

errors. Bob Fenner>

|

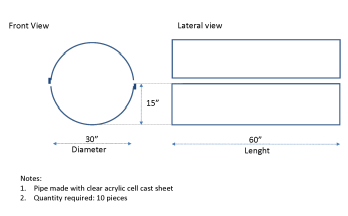

Acrylic pipe for an aquarium, RMF's go

7/14/2009

Hi,

I am interested to build an aquarium using acrylic pipes. This

aquarium will be filled with water (the aeration of the water

will take place in another tank) The diameter is 30 in. and the

length is 50 ft, divided in 10 sections of 5 ft length.

<Interesting>

The simple thing would be to buy the pipes, but I could not find

them. The dimensions could be modified, if there are some

commercial options available.

+ Do you know if there are commercial suppliers of acrylic pipes

for this diameter?

<Mmm, I do not... But I do think this could be

fabricated...>

The option I am currently exploring is to bend 20 pieces of cell

cast acrylic sheet (see attached file) and I have the following

questions: + to calculate the acrylic sheet thickness, I should

only consider the water

column height, which is 30", so the adequate thickness is

3/4"?

<I think you could get away with 1/2">

+ in order to assure no leaks, would it be better to glue the

joints, or to follow a solvent welded process?

<Solvent or sonic>

+ which type of support would you recommend for this design?

<Something sturdy... bead-blasted steel rod, with a

"V" shaped support at the bottom>

+ in addition to visual inspection, is there any other method to

check for cracks, bond failures, or crazing, as a preventive

maintenance program?

<There are non-invasive techniques...>

Thank you.

Francisco Velázquez

<I'd contact Reynolds re:

http://www.reynoldspolymer.com/

Bob Fenner>

Tubular Aquarium. MikeV's go

7/15/2009

Hi,

<Hi Francisco.>

I am interested to build an aquarium using acrylic pipes.

<A different approach.>

This aquarium will be filled with water (the aeration of the

water will take place in another

tank) The diameter is 30 in. and the length is 50 ft, divided in

10 sections of 5 ft length. The simple thing would be to buy the

pipes, but I could not find them.

<There are several facilities that can get it for you. here is

one:

http://www.spartech.com/townsend/acrylic_tubes.html>

The dimensions could be modified, if there are some commercial

options available.

+ Do you know if there are commercial suppliers of acrylic pipes

for this diameter?

<Yes, see above.>

The option I am currently exploring is to bend 20 pieces of cell

cast acrylic sheet (see attached file) and I have the following

questions: + to calculate the acrylic sheet thickness, I should

only consider the water

column height, which is 30", so the adequate thickness is

3/4"?

<You can go a little thinner as it is tube and pressure is

applied evenly to all surfaces. you should be able to use

5/8" (16mm) + in order to assure no leaks, would it be

better to glue the joints, or to follow a solvent welded

process?

<Solvent welded.>

+ which type of support would you recommend for this design?

<That is largely dependent upon where the tank is going to be

displayed At a minimum, supported at each joint and midway

through each span.>

+ in addition to visual inspection, is there any other method to

check for cracks, bond failures, or crazing, as a preventive

maintenance program?

<None that are user friendly that I am aware of.>

Thank you.

Francisco

<My pleasure, MikeV>

|

|

Re: Acrylic pipe for an aquarium 7/15/2009

Thank you Bob.

<Welcome Francisco. Please do send along some images of your

project... In fact, do consider writing up your experiences in an

article for sale to the pulp and e-zine outlets in our interest.

Cheers, Bob Fenner>

Re: Acrylic pipe for an aquarium 7/15/09

Thank you Bob,

it may take some time for this development, as there are many

uncertainties, but certainly it would be a very good article. I

will let you know.

<Thank you>

One more question. If I need an acrylic tank, lets say around 30

inches in diameter, and 44" height, constructed with a cast

acrylic sheet, thermoforming: is a thickness of 9 mm

adequate?

<Mmm; I'd rely on the fabricator to tell you... but would

go with 12 mm minimum myself>

The seam will be welded along the length. The tank will be filled

with water.

Would it work to put a steel belt around the reservoir to add

mechanical strength and avoid a thicker acrylic?

<No; not a good idea>

I know the optics of the acrylic is affected, but this tank is

for a laboratory.

Best regards,

Francisco

<Do contact Jim Stime, a friend who does such custom installs,

large round acrylic... re... I'm cc'ing him here.

BobF>

Re: Acrylic pipe for an aquarium 7/15/09

Hi Bob and Francisco,

Cylinder tanks are very very expensive. I have known of three

cylinder tanks in the LA area. Two of them were seamed and they

both split their seams. One was local and flooded a surf clothing

shop, the second I only heard about.

The third is a 'spun-cast' seamless cylinder that I

installed myself locally ( 44" diameter X 66" tall ).

You can see it in many of the LA Fishguys aquarium reality video

shows on-line.

If cost is an issue or you have an area that would not be

affected from a seam failure of the tank then go for the seamed

version. If you have the money and are looking for a safer tank I

recommend the 'spun-cast' version. Note that this version

has specific predetermined diameters and depending on who your

vendor is you may be forced to buy a certain length / height as

well.

Jim Stime, Jr

805-241-7140

Aquarium Design - www.aquarium-design.com

MyFishTank.com - www.MyFishTank.com

Midwater Systems - www.Jelliquarium.com

LA Fishguys - www.LAFishGuys.com

<Thanks much Jim. See you soon... IMAC west I guess; end of

the mo. BobF>

|

|

A Good Laugh 09/20/09

I was looking at my website today and found this thread. One of

my sites members Chris, ( a really nice great guy btw ) was DIY

ing a sump for his reef tank. After completing the sump (and

eating dinner) he realized that the 2 containers he had used to

hold the baffle in place were sealed inside. The look on his face

is priceless. lol A Jenkins

<Wot a hoot! Am sure SeaChem will be happy to see another ap.

for their line... Heeee! BobF>

|

|

Thank you in advance... Your site is great! Acrylic

sourcing 4/11/09

Hello,

<Ryan>

Do you happen to know of a one stop shop supplier (with a variety of

colors, etc.) of acrylic plastics close to Minneapolis, MN?

<Mmm, I do not, but I do have some ideas...>

Sorry for such a boring question! I keep finding wholesalers, and none

seem to be specialized in plastics. I only need a little bit once in a

while because I'm a student. Perhaps 24"x24"x1/16"

to 1/4". Any suggested

online sites with good prices and staff will also be considered. Thank

you...

I will be making small scale architectural models and will be cutting

with a laser.

<Neat!>

Any advice on which Weld On formula (or other) would be the best?

<Likely #16 here>

I would like it to set very quickly for small pieces, without clamping

if at all possible. I will also want to use a syringe like applicator

so it doesn't get too messy. Thanks again!!!

Ryan

<Take a look in the on-line and in-print "Yellow Page"

directories... In a town of such size there are likely a few outlets.

In this thickness, even the larger "hardware stores" (Home

Depot, Lowe's) will likely carry sheet for resale. Bob

Fenner>

Thank you in advance... Your site is great! ScottV chimes

in 4/11/09

Hello,

<Ryan>

Do you happen to know of a one stop shop supplier (with a variety of

colors, etc.) of acrylic plastics close to Minneapolis, MN?

<Mmm, I do not, but I do have some ideas...>

<<I have a few, but for the quantity you are talking about you

may be better off going to a local store and buying "scrap"

material. Even Home Depot or Lowes carries an extruded acrylic that

machines better than some of the cast acrylics out there.>>

Sorry for such a boring question! I keep finding wholesalers, and none

seem to be specialized in plastics. I only need a little bit once in a

while because I'm a student. Perhaps 24"x24"x1/16"

to 1/4". Any suggested

online sites with good prices and staff will also be considered. Thank

you...

I will be making small scale architectural models and will be cutting

with a laser.

<Neat!>

Any advice on which Weld On formula (or other) would be the best?

<Likely #16 here>

<<If this is indeed laser cut, to a good point of precision, do

use #3 for a fast setup. Scott V.>>

>>Oh! Want to state my reason/rationale for the #16... I have

found that folks who are very new to acrylic work need more time,

jelly-like solvent, even if the pieces are "jointed" or

precision-cut... RMF<<

I would like it to set very quickly for small pieces, without clamping

if at all possible. I will also want to use a syringe like applicator

so it doesn't get too messy. Thanks again!!!

Ryan

<Take a look in the on-line and in-print "Yellow Page"

directories... In a town of such size there are likely a few outlets.

In this thickness, even the larger "hardware stores" (Home

Depot, Lowe's) will likely carry sheet for resale. Bob

Fenner>

Cylindrical tank. Acrylic des. 11/14/08

Dear Crew, Hi! I am a big fan of your website and truly appreciate the

help and information you are giving everyone. I am building an Acrylic

aquarium which is cylindrical in shape. It is of 8mm thickness(5/16th

of an inch) thickness which is a little over a quarter of an inch. The

diameter is 28 inches. What is the maximum height I can make it without

having the aquarium break. The acrylic is going to be die cast type not

extruded. Also what would be the capacity of the tank in the suggested

height in Gallons. Thanks for your advice in advance. Kind Regards,

Raghav Kochhar. <Mmm, I wouldn't go over 20" in height with

this thickness and type of material... the volume... Pi R squared times

the H (divided by 231 cubic inches per gallon)...

http://wiki.answers.com/Q/What_is_the_answer_for_finding_the_volume_of_a_cylinder_8_height_and_3_base

here would be about 53 gallons, before taking out volume for gravel et

al. Bob Fenner>

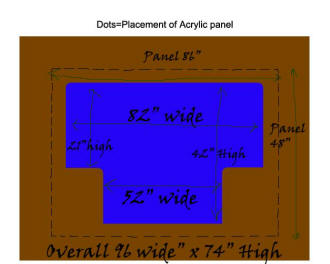

| Acrylic Build Question 02/07/08 I am

currently looking into building a wood tank with a large viewing

panel on the front and a small one on one side. My question is

about the large one. Would 1" thick acrylic be good for an

86" x 48" panel? >... no< The water level would be

over the top of the panel. I have posted a picture of the tank

design (sorta bad picture). What do you think, is 1" good

enough? <Will deform too badly, fail...> The water height

would be about 60-65" total the extra 10-15" would be the

bottom bracing and some space at the top for lighting and fans.

<... how do you intend to seat/seal this viewing panel?> The

panel would be a little of the bottom of the tank so there maybe

say 5" of water then the panel for 48" then water for

another 8-10" or so above the top above the panel. A little

background on why this size tank, the only way for me to upgrade

tanks at this time is to make it fit in the spot my current tank is

in, so taller it has to be. Here is a picture of what I am thinking

http://www.marinelifeweb.com/woodtank/images/front2.jpg Thanks,

Eric <... I would use a minimum of 1 1/2" thick material

here... And read over the DIY tank making materials archived on

WWM... Am concerned re responding just directly to your query

here... as it may well be leading you astray by not addressing

other, vital issues. Bob Fenner> |

|

|

Acrylic Tank Construction Advice...Going Rimless?...Best To Consult

A Tank Builder/Manufacturer 10/03/07 Gentleman, <<Greetings

Dennis...and BTW...very capable Ladies here as well>> I am

constructing a large acrylic aquarium (50x50x30). <<This is

inches I presume?>> I intend to use 3/4" acrylic for the

bottom and sides and initially wanted to keep the top open; but

realized this probably wouldnt work. <<Mmm, no...not at this

height, with this thickness of acrylic>> At best, this would

leave a tank with heavy bowing on all sides. <<Very heavy,

yes...>> At what acrylic thickness would you use to keep an open

top and also prevent any bowing? <<Hmm...can only speculate, but

likely thicker than is practical (1.5 or more)>> If this is not

practical, then what width would you use for a Euro-brace that was

1" thick over the top of the aquarium? <<One-inch is

probably not heavy/thick enough for the Euro-brace to keep the

dimension small. I have a 30 tall acrylic tank made from ¾ material

(sides and top) that has a 7 apron around the top perimeter WITH two 10

cross-braces (8 tank). The tank does not bow, but is quite the pain to

work in so I well understand your wish to go rimless>> Regards,

Dennis <<I very much suggest you poll a broader audience and/or

speak to someone who manufactures such tanks as a matter of routine.

You could either contact a manufacturer like Tenecor, or give the DIY

forum on Reef Central a try. Tenecor was very helpful with

suggestions/advice when I wanted to make some modifications to my

tank...but then I bought it from them. The RC forum has a couple guys

who manufacture acrylic tanks who routinely peruse the forum and are

willing to answer questions/provide advice (one called Acrylics (James)

comes to mind...you might even try sending him an email or private

message). Good luck with your project. EricR>>

| Acrylic fabrication 2/12/07

Hello....I am building some acrylic fish tanks (1/2 in cell cast

36*24*24 full top panel with cut outs) and was wondering what

method you use to heat the acrylic for bending. I would

love to be able to use 1/2 inch and bend it. <Mmm... well... you

could build/fashion a heat table as we and others have... with an

element (electrical) flanked by two cold water pipes (flat)... and

a second-time piece and standards for tilting the acrylic panels up

to the appropriate angle in time... But I would likely call, use

these at a local fabricators rather than build my own for a one

time use> Also do you use shims when bonding with the Weldon 3?

<Not usually... but a good idea to use gigs or wood clamps at

least to hold all in relative place...> I have heard that using

small wire shims will raise the panel a SMALL amount. <Yes...

too much with thin material (under an inch thick let's say)>

This supposedly allows better flow of the solvent. <Mmm... not

necessary... the solvent will easily flow/occupy the gap if cut

right, fitted closely> You remove them just after applying the

solvent and then lightly clamp the panels. <... Uhh... I'd

be practicing with some "cut-offs" if I were you...

before trying the "real thing" here> I usually have

good results not using them but there are a few places on the joint

that do not appear to have full contact. <Not good... bad

cutting...> The joints do not fail but they are not crystal

clear all the way like the store bought tanks. Looking

for any tips you may have <I'd be inserting some corner

bracing...> Also how do you start building a tank? <?> I

started by lightly clamping the front. back and sides together. I

then placed that onto the top panel (upside down) that I had

already cut out for access. <Good... this is how I, and our

"old" companies used to do... for small/ish systems> I

then solvent welded the top and the sides. After that set up I

flipped it over and set it onto the bottom panel. I reached through

he top panel cut outs and solvent welded the bottom panel. Here

area couple pictures of the 90 gal I just made. <Very nice!>

I added the back panel to the black top after these pictures were

taken sorry for all the questions but I value your advise on this.

LOVE this site!!. I am getting ready to build a new 8*24*24 240 gal

tank to go in the wall <Sounds like you're ready! Cheers,

Bob Fenner> |

Re:... acrylic tank white-out seam

repair? 2/14/07 Ok so I should get some 1/2 inch

wide and 1/2 inch thick square stock to use as

reinforcement along the inside joints? <Yes, I would for sure...

Do take a close-look at the square stock... often it is only really

square on two sides... the others being convex... Of course you

want the truly square faces against the repair> Also I was

wondering if it would be safe to router the edges of

the tank so that they are a bit round and not such a

sharp corner. <Yes... as long as the joints themselves are left

intact> I was thinking a 1/8 inch or so. I

was prepping the next sheets I am using for the tank I am building

now. I used 400 wet sanding to remove any machining marks and

make a totally smooth surface to solvent weld. Hoping for some

crystal clear welds :) <Yes... Want to mention (for

you and posterity) that you might want to look into a "higher

number" Weld-On product (more gel-like)... and perhaps better

gear for cutting the sheets... should be flush, not require any

sanding...> Thanks again for the help!!

Ed

<Welcome. Bob Fenner> |

| Re: Acrylic fabrication -

02/15/07 OK I will router the edges some to knock off the

corners and I will make sure that the square stock I use as

reinforcement is perfectly smooth on the contact

sides. I was also wondering about a triangular rod that

would fit into the corners.. any ideas on that? <Have

used this as well... Will work, yes> The place that I get the

acrylic from cuts the panels to my specs but I am sure they

are not using a $200 blade either to make the edges finished.

<Mmmmm... am surprised the edges aren't more

"clean"... Do they have suggestions re sanding them

smooth?> The Wet sanding worked awesome. I now have welds that

are 99% crystal clear. <Mmm... okay> I took a 2x8

inch x .50 inch scrap and solvent welded another identical piece on

top as in a "L" shape. I then cut

1.5 inch strips of sand paper and used it as a guide

block for sanding. This worked great for keeping

me square on the edge <Sounds good> I used the

#3 because I was under the assumption that it

was the solvent of choice I have read

that the #16 gel was not as strong and

therefore not to be used for actual joints but ok for baffles and

such.. I heard the # 4 was just a tad bit slower in set

up/dry time I used a similar solvent to the #3 about 15

yrs ago when I made my first 240 gal tank. <As an important note

here... I met with friend Leng Sy/EcoSystem yesterday... he was

down picking up a good quantity of #3... Said that Weld-On has

changed formulations in recent years... the number 3 is what most

everyone uses on the west coast...> It held up great

but unfortunately was dropped during a move and suffered

some cracks. The place that cut those sheets for me used

a blade that did leave a really level edge on it.

<Good> Again, thanks so much for your input and advice. I

appreciate the time and effort it takes to do this. Ed

<Thank you for the input and clarifications. Much appreciated.

BobF> **On a personal note I have owned a Mortgage Company for

18 years so if you have any Mortgage related questions please

feel free to ask :) <And for this!> |

Re: Acrylic fab... and fab tools!

2/18/07 OK I went out and bought a nice Delta planer this

weekend. <How nice!> I can now clamp the panels

together, run them on the planer and make them all

the exact same size and finish the edges in one move :)

This thing is just awesome, what a time saver. It weighs

@200 lbs so it was a bit of a load to get down in my

basement by myself, but I won the battle :) <Oomph!> I built

the base of a skimmer I am making for a guy and the joints are

just beautiful! <Great> What is your opinion on Chemcast

Acrylic? I have read in one place from a very experienced tank

builder not to use it for aquarium use. I searched trying to find

more info but could not. <Mmm... I have heard similar opinions

from folks re this Mexican co. product... though they are

(admittedly) one of the largest producers in N. America... I have

heard, what I would couch as rumours, that it (as a general stmt.)

is "too soft"... that sometimes their sheets are

inconsistent in thickness... quality> I hope he is wrong but if

not then the 2 tanks I just built will be reptile tanks

I guess. Thanks again Ed

<Good attitude. Thank you for sharing. Bob Fenner> |

|

|

Drilling Acrylic Can anyone offer some experience/advice for the

placement of holes in acrylic tanks in relation to the seams? I'm

setting up a large reef system and I'm plumbing 1 inch bulkhead

returns (two per end) in the ends of the 3/4 inch acrylic tank. I want

to place the bulkheads as high as I can and was wondering if I can

drill the holes right next to the top seam? My understanding is once

acrylic is solvent glued it's essentially all one piece, yes?

Thanks! Eric <My general "rule of thumb" is to leave gaps

at least as wide as the cut out diameter from seams. You can adjust the

water height in the system with plumbing distal to the tank if this is

a/the concern... either ell's, tee's or valves. Bob

Fenner>

Acrylic pricing In my never ending search for better pricing

on acrylic sheet, I have noticed a great difference in pricing by web

searching. Is the only difference the competition between companies in

their area? Or are there other circumstances that I should be aware of.

<There is some local variation, but the trade in acrylic is highly

layered in terms of master distribution, volume discounting> I have

found one company out of Utah that sells a 4x8x1/2 sheet of cell cast

for about $195 + shipping (truck line) and free cutting down to 24 x 48

for UPS shipping. So far this is the best deal I have come across.

<This is indeed a deal... do check re the quality of the sheet

however... buy brand name/s if you can... as there is some important

variation in this product... some is quite flexible... some more soft,

easier to scratch> From a business point of view, are there any

lower prices out there to either maximize the bottom line or sell the

end product at a lower price than the competitor? What info if any can

you give me? Thanks again for your glorified answers oh wonderful

master. <Good questions... as I don't have ready answers (!)...

if you can deal in volume (not likely), there is quite a bit of

"wiggle room" in negotiating. Bob Fenner>

Re: acrylic pricing I emailed this company in Utah and they

wrote back they carry Lucite L, Chemcast and an import sheet. What is

the best of the 3? and are they good for aquariums? <Very likely the

Lucite L... there are specifications for all acrylic... you should

request these spec.s and endeavor to understand what they represent.

Bob Fenner>

Acrylic pricing update would I contact the manufacture

directly for the specs? <Joe, not to step in here but just wanted to

let you know some things. I'm sure Bob will also jump on this

question. Acrylic pricing is currently going through the

roof because as you know it is an oil based product. I know that the

cost of the custom tanks we've been making has pretty gone up

simply because prices of acrylic have gone up so high. Most local

plastic places will meet online prices or come pretty darn close and

its pretty standard for most acrylic places to do at least three

"cuts" per sheet. Also, generally if you buy more than one

sheet you can get them for a much better price than if you just buy one

sheet. They generally have prices for one sheet, two to nine sheets and

then nine and above sheets. Most of the specs on acrylic

brands can be found online because most of these companies have gone on

the web. But let me also make you aware of something that's out

here recently and I'm not telling you that this company is guilty

of it, just making you aware of what to ask. Make sure you know the age

of the acrylic. While acrylic doesn't really age there

can be problems with what's been on the acrylic while it is sitting

around so be sure and ask the AGE of the acrylic that these gentleman

are selling. Also, there are rumored to be problems with the

imported acrylic and gluing. I personally haven't used it so

can't tell you whether that is the case or not. One thing I look at

closely when I look at acrylic specs is the ability of light to pass

clearly through it. Just my two cents. MacL> Re:

acrylic pricing would I contact the manufacture directly for the

specs? <You could, yes. They should be available on the Net though,

and distributors have these as well. Bob Fenner> Re: acrylic

pricing I went to the manufactures websites for Lucite and Chemcast

and Lucite seems to be the better of the two products. Chemcast as far

as I can tell is an import from Mexico. <Yes. Bob Fenner>

- Building My First Acrylic Tank - Hi There,

First off, I've been addicted to your site and check the new

FAQ's daily for useful info. Anyway, I want

to start building my own acrylic tanks and I have found a detailed

instruction book on the web which shows exactly how to design right

through to how to use the solvent's properly. The only

thing is I not completely sure on thickness. Since this is

my first tank I am starting small and would like to build about a 30-40

gal tank for my 2 dwarf gouramis, yo-yo loach and red fin

shark. My problem is that the instructions say that 1/4 inch

is good enough for tanks up to I think 12 inches (I have misplaced this

valuable info right now) and 3/8 inch is good up to 18 inches

high. I have read on your site that length of a tank

doesn't matter only height but can I really build a tank that is 12

inches tall and 48 inches long out of 1/4 inch? <I wouldn't...

it's always worth while to overbuild, have a margin of error.

Likewise, the thickness will really be determined by the materials. You

can get specifications from the acrylic manufacturers that will serve

as a guide.> This wouldn't be the an ideal tank but for argument

sake is this actually realistic. I am obviously asking

because 1/4 inch is so much cheaper but it will cost a lot more to

clean up all the water when it lets go. <True.> I am still

planning to use 1/4 inch for my first tank just so I don't waste a

ton of money on a failed tank. I will build a tank smaller

with a divider (basically two separate tanks in one) for my

feeder fish (I know they're not the best but my red bellies refuse

dead food) so that one side is QT for a month and then get moved to the

"safe to eat side ". This would be about a 20-25 gal

tank. Your expertise would be greatly appreciated.

<Well... as an experimental build, I'd encourage you to hone

your skills with the cheaper materials. Tanks can be placed outside on

a flat surface and filled with a hose to see how they hold up. Once you

have your design and technique down, then go for the more expensive

materials.> The real reason I want to start building my own is my

piranhas are going to be needing a bigger tank soon (next 3-4 months)

and I would like to build a tank for them which is going to be around

60-75gal as I only have two. Thank you in advance Mike P.S if you know

of any ways to get my piranhas to eat anything but feeders that would

be great. I've tried mixing live with salmon chunks,

krill they eat sometimes, but usually they refuse and then the fin

nipping and body wounds begin. Starving is out of the

question as one has just recovered from an eye injury caused buy the

other during my attempt to starve them so they would eat something

else. They are about 4 and 4.5-5 inches long right now and

GROWING! Thanks! <Is perhaps the major drawback of

piranhas... think your plan to quarantine feeders may be your best bet,

that and continue trying to mix in other foods from time to time.

Cheers, J -- > Bonding Silicone/Lexan Plexiglas Could you

tell me if silicone will attach Lexan Plexiglas to a glass aquarium or

if you can only attach glass to glass with silicone? Thanks, Amy

<Silicone will weakly bond Acrylics, but are not to be trusted in

aquarium applications of any real size/depth. Solvents for this purpose

are the route to go. Bob Fenner> Acrylic question Hey,

WWM-ites (particularly the acrylic construction experts), <Hi Glen,

I don't know what you consider an expert. I just delivered a six

foot acrylic tank so my family builds them. Hopefully that qualifies

me.> Things are plugging right along with the 55 gal community

tank. We're stocking up, and nearing our piscine

limit. Chemistry is performing nicely, pH running 7.0-7.1

and our weekly 20%+ water changes are keeping the nitrate levels at

just over 10 ppm. We've moved the eight surviving baby

Swordtails to a 5-1/2 gal tank, along with a Panda Cory and a really

cool Mayan statue head (just to irritate my wife!)<I LOVE

IT!> In the big tank, we've replaced the fake

driftwood arch with a real cypress driftwood arrangement (for the

Otocinclus to gnaw on), and have replaced most of the fake plants with

real ones, including a line of Vallisneria, quite a Cabomba forest,

dwarf and giant hair grass, planted (huge) and floating watersprite,

java moss, and red Ludwigia and Alternanthera. We're waiting for

the plant-carrying LFS to get a red water lily to finish our live plant

assortment. <Get a dwarf lily or you might have size problems

lol.> We've upgraded to a four-foot 110-watt AGA compact

fluorescent fixture, which really makes the colors snap. The plants are

doing well with the higher light level (duh!), and I'm hoping their

consumption will start reining in the rather amazing algae growth.

<It will, I know its got to be frustrating though.> I have

roundly chastised myself for overfeeding the fish (new owner,

poor-starving-fishy syndrome) and causing the algae bloom, but I'm

going to let nature take its course (thanks, once again, to the advice

on WetWebMedia!) I haven't decided whether I'm going

to do any CO2 augmentation for the plants. Maybe in the

wet-dry, which brings me to the topic of this query. <Bring it

on!> I've designed a DIY wet-dry filter, big enough

to support multiple tanks when we get into our non-rental in a year or

so. <Ooooo nice.> The sump portion will be 24x13x13, and the

removable biotower will be 16x16x12 (biomedia capacity just over 7-1/2

gallons). 2" deep floss/media/drip tray drawer, Mag 7

pump, Durso standpipe fed by a Busko surface extractor, etc. etc.

etc. Investigating the types and recommendations for the

acrylic has me going in circles. <Ahhh that one I can help you with,

we've made many, many sumps and wet/dries.> Questions (and

please don't be gentle - if the answer is "quit obsessing, buy

the cheap/expensive stuff and build it", feel free to say so!):

<I would never say it in that way, to my way of thinking you simply

cannot do enough research when you are doing something for your

tank!> I'm leaning toward 3/8" acrylic, but 1/4" is

sure cheap! <You really do not need the 3/8, with what you have

designed you won't get any bowing. Your height really determines

the stepping up in size of the acrylic. If you keep each piece cut

under 24 inches tall you should be just fine.> I've designed in

3/8" square cross braces in the biotower and sump, to control

bowing in the longer spans of plastic. <The bowing won't be

significant enough that you'll need the 3/8ths, simply brace with

1/4 and you'll be just fine.> Total catastrophic

power-outage water load will be a bit under twelve

gallons. I know the 3/8" will provide structural

integrity and the "gee whiz, look at the pretty acrylic"

factor, but would 1/4" really work just as well? Of

course, this ignores the 5/16" and 9mm stuff! <I promise you

that it will work as well. Now just a few

hints. Route the edges because plexi is sharp and it will

cut you, if you route the edges or you flame polish them regardless of

the size it will eliminate most problems in cutting.> Most of the

tank-building sites say (essentially) not to think about anything less

than cell-cast acrylic. I've seen all the reasons why -

superior clarity, harder surface, nicer machining characteristics, etc.

In small quantities, cell-cast is danged expensive - I haven't

found it for anything under $7/sq. ft. for 3/8"

material. Continuous-cast, on the other hand, can be had for

just over $4/ sq. ft. for 3/8", and extruded less than

that. Other than the "gee-whiz" factor, is there a

compelling reason to go with cell-cast for this project? <Cast

acrylic, continuous cast acrylic and extruded acrylic are types of

manufacturing processes. Each process is made from acrylic with

different properties and subsequently show different characteristics in

the fabrication process and in the finished products. Cast acrylic is

the most dense and therefore the strongest. It also tends to bond with

the strongest seams. For aquarium applications use domestic brands

(Polycast, Acrylite GP, Plexiglas G material) I use the Plexiglas G

most frequently. Continuous cast material have a density close to Cast

materials. (Lucite material) Good for small aquariums, filters and

museum quality display cases. Extruded is an inexpensive low-density

material for Point of purchase displays, signs etc. I just don't

think with extruded that you will get the attachment you need with the

water pressure.> What will be the disadvantages if I use continuous

cast? I'm leaning away from extruded - is there a

particular brand that would justify my rethinking this? If

cell-cast is really that much better/easier to work with/more stable

over the long term/other, I can convince myself to spend the extra

money (over continuous-cast), but why spend

unnecessarily? Should I spend any time looking at Lexan or

other polycarbonates, or is that super-duper-extreme overkill?

<Lexan is beautiful but sooooo expensive. Frankly I can't touch

it here.> If you have any other suggestions, comments, guidance, or

whatever, I'd appreciate hearing them. <I think you'll be

happy with the thinner Plexiglas for this particular project.> Once

again, thanks for your fantastic site! I noticed your

"support this site" link at the bottom of the

homepage. Is it new, or have I been that

inattentive? I'll be chipping in as soon as I clear it

with the Bride. <We are trying hard to keep the site free and of

course the answers. But it takes a large amount of money to maintain

this site. I'm glad you find the site helpful and please let me

know what you do and how it works. MacL> Glen

Another acrylic thickness question Hello to all.

I stumbled upon your site about 6 months ago and now read it daily ...

a wealth of information and a joy to read. I am in the planning stages

of my dream tank: a 300 gallon (96" x 24" x 30") FOWLR

(I love angels and butterflies!) Most of the inhabitants and some

equipment will be coming from an exiting 125. I have everything

planned, including equipment requirements, plumbing diagrams, even my

livestock wish list. When I went to order the tank, I realized I had

one unanswered question. The tank is being built by a company called

Tru-View and will be made from 1/2" acrylic for the sides and top

and bottom. My existing 125 (72" x 18" x 20") uses

3/8" on all sides except the back which is 1/2". The

thickness of the new tank has me concerned. I spent several hours

reading you posts regarding thickness recommendations and am still

confused. I don't mind a little bowing, but I do live in earthquake

country (Northern California) and want a tank that will be as safe as

possible. The tank will reside on concrete slab in a finished garage /

playroom. So, is 1/2" good enough? Or would you recommend

5/8" or 3/4"? Thank you for your time. Dana

>>>Hi Dana, I'm very familiar with TruVu, and have owned

many tanks made by them over the years. They are actually made locally

not far from my house. I've also had a number of tanks custom made

over the years. What you need to be concerned with is

"thrust" which is the pressure the water exerts against the

inside walls of the tank. This is a function of the height of the tank,

and the width. As long as you stay below 26", and no wider than

say 32", 1/2" works, even if the tank is 10 feet long.

Although 1/2" is standard on certain tanks, and will work just

fine on a 24" high tank, any higher and I'd go up to

5/8". Since it's only 24" wide, no reason to move up to

3/4". It will NOT provide more earthquake resistance (I live in

California too) but it will not bow nearly as much, and it will be

stronger. The thicker the acrylic, the more surface area on the joint.

Just a piece of mind thing. In general, even on smaller tanks, I always

kick the thickness up a notch. Cheers Jim<<<

Plastics Suppliers 2/15/05 Hey all,

<howdy> Do any of the Pittsburgh folks know where I can go to buy

acrylic scraps and/or sheet material? I am looking for pieces to build

a sump. Thanks! Ed <locally is a bit expensive at places like

Cadillac Plastic if still in business. You may want to simply do mail

order. US Plastics Corp (Lima, OH... Google them) has a big inventory,

not the cheapest prices though, but great customer service and fast

shipping from OH. Anthony>

- Refugium Construction - Hi, I would like to thank all of

the crew members at WWM for all of their quick and helpful responses

they given me. I tried to search for a question similar to mine, but I

couldn't find what I was looking for. <Seems odd... I

answered a similar question not three days ago.> I am working

on a 15 gal. sump, actually it is running, but I do not have it

chambered so I can make it a refugium. I think to convert this I would

just need to seal two panels, one on each side, so that the center

would have most of the flow going over the top and not affecting the

middle chamber. My first question is, what would the best material to

use as panels? <Glass or acrylic - either will do, would use

the one that's easiest to get your hands on.> I was

thinking Plexiglas from Home Depot. <Sure.> Secondly,

is there a silicone sealant that can be used underwater without adding

any pollutants to the tank? <None that I would suggest - you

should really plan on doing this work in a dry tank.> Or am I

just going to have to drain the tank and use the sealant?

<Yes... this is your best bet.> I know that your site

recommends using 100% silicone sealants without additives, will the

silicone package say that it is aquarium safe or am I just to assume

that it is? <If you pick up the silicone from a local fish

store, you should be all set... even though Home Depot does carry

silicone that will do the job, they have too many tubes of the wrong

kind that would be too easy to grab. There is such a thing as

"aquarium sealant" that can be obtained at your

LFS.> Thank you again for your help. <Cheers, J -- >

Acrylic tank question Hello, I am building my

own acrylic tank, the dimensions are 48"W x 96"L x 48"D.

Is 1" - 1 1/4" acrylic sufficient enough to hold water?

<Mmm, well... it is... but... if this is for a "fish tank"

and there are no really pressing desires to make it this tall...

I'd cut the height down to three feet or so... much easier to work

on... and whether the setting is high/low (standing, sitting), a better

"dimensional aspect" IMO... the tank will bow pretty

noticeably even if braced... and from your website am sure you are

aware of the cost difference between the one and a quarter... or what I

would use here (if going with the four foot height), one and a half...

Worth it... structurally and from a resale point of view. Bob

Fenner> Thank you for your prompt response. Thanks, Bob North Please

visit us at: http://www.splashescreative.com/

<Neat!>

Re: acrylic tank question Bob, Oops! I

made a mistake. This is a prop to be used for a magic illusion however

the dimensions I gave you were wrong. The correct dimensions are

48"W x 96"L x 96"D. We are committed to the 8'depth

dimensions and cannot waiver from this. (I've already talked him

down from 12'). We will be using full 4'x 8' sheets of

acrylic. Do you think that the 1 1/4" thickness will hold water

and the magician without bowing or breaking? <Not worth the risk.

Our old companies used to fabricate acrylic aquariums (in addition to

other work)... and for any tank of eight foot depth I would NOT use

less than two inch cast> What thickness would you suggest? I

appreciate your promptness. Thanks, Bob North <Do a bit more looking

about... but, please... no less than two inch. Bob Fenner>

Appropriate acrylic adhesive for reef tank Hello, <Hi

there> I purchased an adhesive (Devcon Plastic Welder) for my DIY

skimmer and I have a quick question regarding any problems with this

adhesive. Will this adhesive leach any harmful chemicals

after it has cured 24 hours? Any input will greatly be

appreciated. Thank you. David <No worries... their MSDS:

http://www.tapplastics.com/uploads/pdf/MSDS%20Devcon%20Plastic%20Welder.pdf

Once cured there is none left... not a glue... but a solvent. Bob

Fenner>

Acrylic DIY supplies 6/13/05 Hello, I've been

searching on your site for some recommendations for acrylic or

plastics. I want to make a black acrylic box open in the

bottom and top with a slot in the middle to hide my Turbelle pump in

the aquarium. The question I have is where can I find a

supplier? Are the easy to find where I live, Dublin, CA or

is there one you can recommend on the internet? I'm

looking for the black acrylic. Thanks, Brent <Most major

metro areas have an acrylic supplier. Check your local

yellow pages under "plastics - sheet, rod and